MECHANICAL TORQUE MULTIPLIERS

|

|

Advantages Of Torque Multipliers :

- The ratio stated is the true torque multiplication factor.

- No correction charts are needed to determine torque output.

- Strong, safe Anti Wind-Up Ratchet available on most models for safe and comfortable operation.

- A wide range of alternative reaction arms are available as per customers requirement, making the Torque Multiplier adaptable to many applications.

|

|

| Standard Series Anti Wind-Up Ratchet |

|

Anti Wind-Up Ratchet (AWUR)

With any high ratio gearbox (25:1 or more) a certain amount of wind-up (spring) has to be taken up before any useful tightening work is applied to the nut.

Each time the input device is released, the wind-up will rotate it back against the direction of operation.

The Anti Wind-Up Ratchet retains all of the wind-up forces as they are created, with the following benefits:

- The torque input device can not fly backwards against the direction of operation if it is suddenly released.

- Without an Anti Wind-Up Ratchet, it will often be necessary to continue to make 360 sweeps with the torque input device otherwise the multiplier will ‘unwind’. However, obstructions will often make this impossible.

- With an Anti Wind-Up Ratchet fitted, the multiplier becomes locked onto The nut because the reaction plate is held hard against the reaction point. This means that even used upside down, the multiplier will support it’s own weight.

Safety Note: Additional support is recommended as failure in the bolt, socket or multiplier will release the wind-up forces and cause the multiplier to drop.

|

|

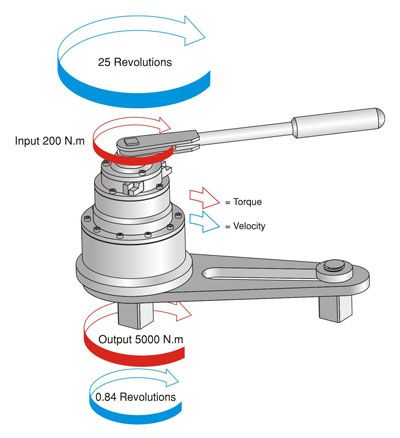

Features of Hand Torque Multipliers

- Accuracy better than ± 4%.

- Precision tightening and loosening of all heavy duty fasteners.

- Low energy input with high torque transfer.

- Higher capacity multipliers are furnished with strong ratchets (Anti-wind up mechanism) allowing jobs to be performed easily, efficiently, and safely.

- Precision Manufacturing ensures long life and premier quality.

- A groove on output Square breaks if over loaded in excess of 20% of its capacity.

- Highest possible load factor is guaranteed due to design and use of forged components.

|

|

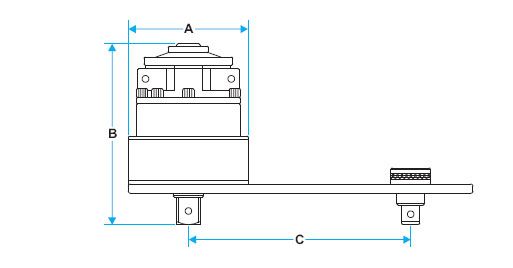

Standard Series, to 47500 N.m

|

| Model No. |

Capacity |

Ratio |

Input

Square |

Output

Square |

A

Ø

|

B |

C

min |

C

max |

Weight |

| N.m |

Ibf.ft |

inch |

inch |

mm |

mm |

mm |

mm |

kg |

lbs |

| BTM-6 |

3400 |

2500 |

5 |

3/4 |

1.1/2 |

136 |

149 |

105 |

260 |

9.20 |

20.24 |

| BTM-6/25 |

3400 |

2500 |

25 |

1/2 |

1.1/2 |

136 |

176 |

105 |

260 |

12.00 |

26.40 |

| BTM-7 |

6000 |

4500 |

5 |

3/4 |

1.1/2 |

168 |

174 |

115 |

310 |

18.00 |

39.60 |

BTM-7/25

Fitted with AWUR |

6000 |

4500 |

25 |

1/2 |

1.1/2 |

168 |

226 |

115 |

310 |

22.00 |

48.40 |

BTW-9/25

Fitted with AWUR |

9500 |

7000 |

25 |

3/4 |

1.1/2 |

195 |

226 |

150 |

350 |

33.00 |

72.60 |

BTW-9/125

Fitted with AWUR |

9500 |

7000 |

125 |

1/2 |

1.1/2 |

195 |

301 |

150 |

350 |

35.50 |

78.10 |

BTW-11/25

Fitted with AWUR |

17000 |

12500 |

25 |

3/4 |

2.1/2 |

220 |

360 |

164 |

480 |

52.00 |

114.40 |

BTW-11/125

Fitted with AWUR |

17000 |

12500 |

125 |

1/2 |

2.1/2 |

220 |

404 |

164 |

480 |

57.00 |

125.40 |

BTW-13/125

Fitted with AWUR |

74500 |

35000 |

125 |

3/4 |

2.1/2 |

315 |

550 |

164 |

480 |

80.00 |

176.00 |

|

|

|

| |

impact sockets

impact sockets  pneumatic lmpact wrenches

pneumatic lmpact wrenches  manual ratcheting spreding wedge MSW-10

manual ratcheting spreding wedge MSW-10  Hydraulic Spreading Wedge HSW-10

Hydraulic Spreading Wedge HSW-10  hydraulic vertical lifting wedge HVW-10

hydraulic vertical lifting wedge HVW-10

impact sockets

impact sockets  pneumatic lmpact wrenches

pneumatic lmpact wrenches  manual ratcheting spreding wedge MSW-10

manual ratcheting spreding wedge MSW-10  Hydraulic Spreading Wedge HSW-10

Hydraulic Spreading Wedge HSW-10  hydraulic vertical lifting wedge HVW-10

hydraulic vertical lifting wedge HVW-10